Patio Door

Picking a Patio Door is never easy – many people have homes with doors that they have to fight to open and close. Other common issues include failing locks and poor thermal performance.

In this article we highlight the five factors that you should take into consideration when looking for a new Patio Door.

1. Thermal Performance

The largest surface component of a Patio Door is the glass, which is also the biggest entryway for energy to escape from you home (or let the cold in). Using Low-Emissivity glass is a must (find out more here) and it’s important to make sure you use the right material for the frames and sash. As we’ve discussed before, Vinyl is the only choice.

The ideal door will have numerous chambers to help dissipate energy transfer and the glass should be held together with a non-metal spacer, preferably a foam spacer for optimum performance.

2. Ease of Use

Patio Doors are used more frequently than windows and as a result have enormous demands on the hardware. A good patio door should be easy to open, requiring very little pressure to move the operating sashes. Locks should engage when the door is closed, without having to jimmy them or struggling to line up.

3. Hardware

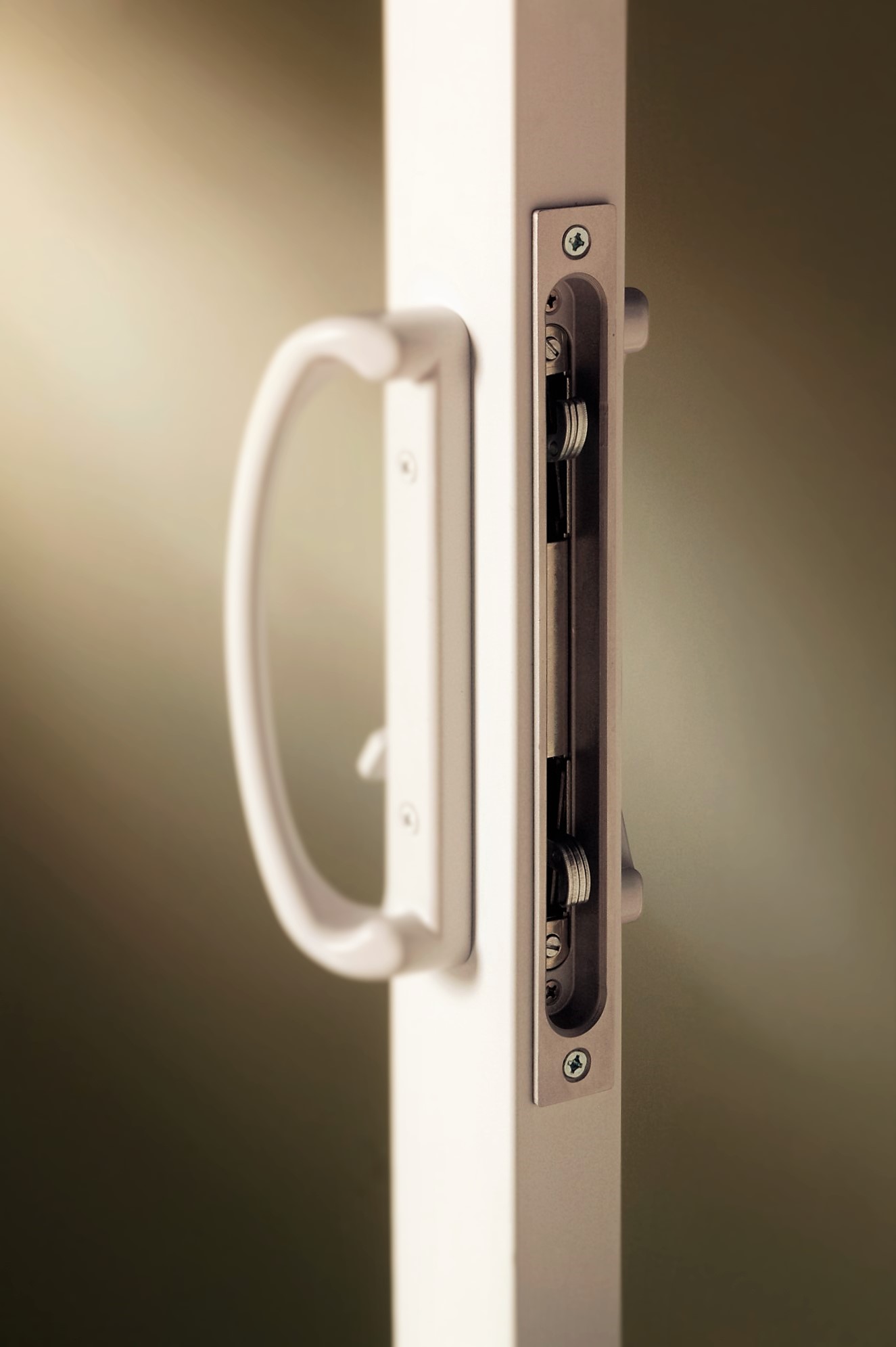

A Patio Door is an entry point to your home – as a result it should have strong, durable and secure hardware. Many doors will only have a single mortise lock, for ultimate security a double-mortise lock should be standard.

The lock should be keyed from the outside and you should expect a foot-lock as standard, to give the option of worry-free ventilation.

4. Customization

You shouldn’t be fitting your home to a door, it should be the other way. This means fully custom sizes and finishes, whether it’s the exterior color, tinted glass or even integrated blinds.

With blinds between the glass there shouldn’t be a compromise of functionality for thermal performance. There are now doors on the market which have blinds and soft-coat Low-E glass.

5. Structural Performance

A Patio-Door is a large unit that has a lot of structural functions. It needs to be strong enough to work in the opening it’s put into, a minimum Design Pressure of 45 is favorable.

To get the best structural performance at the manufacturing level it is essential that the door is made with a four-point welder in the frame, giving it rigidity and a perfect join.

We hope this article has been helpful, if you have any questions please don’t hesitate to get in touch!